Help w custom dining table top

I’m having a custom dining table made. The base will be white oak and measure approximately 68x38. The top is going to be soapstone and is 3cm thick and weighs approximately 500 lbs.

The stone fabricator says the table legs should support the top, but this makes me nervous.

The person building the table said he can add 3-4 horizontal supports (example pic) and it should be fine, but he isn’t familiar with stone tops, as his tables are made with wood tops.

I’m nervous that the advice that the table will support it are not accurate. Will the supports the table maker is recommending be enough to support the soapstone top, or do you have any other advice or recommendations?

Comentarios (32)

Joseph Corlett, LLC

hace 4 mesesHave the base maker have a 2" square tube metal frame fabricated and installed inside the top of the base please.

jennifernelson24

Autor originalhace 4 mesesIs this relatively easy/inexpensive to do? I’m worried he doesn’t have the means to do this. He is out of state and I’m just hiring him to make the wood base. He owns a woodworking shop…I wonder if this is out of his league. Any guidance is appreciated.

klem1

hace 4 mesesIn the building where I once worked all the offices had tables with bases exactly like the one in that picture. I know for fact the table in office above me routinely supported the guy that rented it and his secretary. They weighed over 250 pounds each.

marmiegard_z7b

hace 4 mesesOk, call me timid, but how do you plan for a piece of free-standing furniture that will be so hard to move in your space? Maybe I’m the only one who occasionally needs to move something a few inches this way or that.

jennifernelson24

Autor originalhace 4 meses@marmiegard_z7b I found caster wheels that support 200 lbs each. So I’m hoping that this will work for the rare occasion that I’d need to love the table.

Different styles: but one example:

https://www.vandykes.com/wooden-wheel-ball-bearing-steel-stem-caster/p/225538/

chispa

hace 4 mesesÚltima modificación: hace 4 mesesSure, I would hate to have a dining table that couldn't be moved, but plenty of us have owned and lived with pool tables that were installed and never moved until you sold the pool table or sold the house and left the pool table behind! In our second house the pool table was in the formal living room and definitely not moveable once installed. A good friend had a pool table in her dining room with the dining table top option and that "table" also couldn't be moved at all and it wasn't a problem.

klem1

hace 4 mesesThe camera must be playing tricks on my eyes , the tables in our offices were more so occasional tables some might call coffee tables. Tops weren't soapstone but I swear bases looked exactly like Jenniffer's. Much too low for dining but amongst other things very handy for snacks and coffee. I think wheels would distract from the beauty of a nice top. I'd forget wheels and keep a pallet jack on hand for occasions when table has to be moved.

Easy Renovation | Bathroom Renovation Toronto

hace 4 mesesFor your custom dining table project with a soapstone top, it's crucial to ensure the stability and safety of the table. Here are some key considerations and tips to help you achieve a secure and durable setup:

- ensure the table base is sturdy enough to support the heavy soapstone top

- consider reinforcing the base with additional supports or thicker legs

- consult with a structural engineer or an experienced stone table maker for advice

- check if the soapstone fabricator can provide specific guidelines for support

- explore the option of a thicker base or a frame to distribute the weight evenly

- regularly inspect the table for any signs of stress or bending over time

bry911

hace 4 mesesThe table legs will easily support the top. In fact, a single table leg would easily support the top.

The problem is the apron. The wood apron will flex a small amount under load and the stone is going to crack rather than flex. So, the apron needs to be stiffened. You don’t need a frame built from steel tubing… you already have a frame and building another one is just a massive waste of money.

The table maker needs to remove the two apron stretchers (shorter boards between longer ones) and install a long stretcher parallel to the apron. Then attach plate steel to the inside of the apron boards and long stretcher (as tall as you can get it). I prefer to router a channel and epoxy it in, but you don’t need to do that. The steel doesn’t need to go to the end so you can stop them an inch or two before the corner braces. The purpose is only to stiffen the existing apron frame. You don’t need a new welded frame, you just need a stiffer wood frame.

Then the stringers between boards should be cut shorter and reinstalled between all three of the longer boards (probably with brackets).

jennifernelson24

Autor originalhace 4 meses@bry911. Thanks for the info.

If I were to use a granite top instead..that is milled to 2cm thick and about 250 lbs…do you think this would be ok and solve all

The weight issues?I really love the soapstone, but I’m nervous it won’t work, so maybe if the granite would, I should reconsider.

bry911

hace 4 mesesChanging the stone isn’t going to change anything, all stone is going to have the exact same problem. You have to either strengthen the stone or stiffen the frame. Stiffening the frame is the cheaper and easier option. Any woodworker should be somewhat familiar with stiffening a wood frame, I have to do that with desks, it really isn’t a big deal.

It is $100 worth of steel and two hours to do all the modifications.jennifernelson24

Autor originalhace 4 mesesOk thank you. I thought the weight might have an impact, but it sounds like it won’t. I’ll ask the woodworker about stiffening the frame.

jennifernelson24

Autor originalhace 4 mesesThe granite is half the weight of the soapstone (in case that wasn’t clear)

L.D. Johnson

hace 3 mesesThis sound lovely- and expensive. If you are buying the stone from a fabricator and the base from an out of state woodworker, who will be responsible for any issues with the final assembly in your home?

Please reconsider the casters - unless you've already had the legs cut down to accommodate the height they will add. I don't see any indication on the website that those have a locking mechanism.. While the table will be heavy, it still might tend to move when someone at an end pushes off to get up.

Best wishes for working through the details to get the custom product you envision!

Diana Bier Interiors, LLC

hace 3 mesesI would just have the top the same material as the legs. But that's just me.

Seabornman

hace 3 mesesCould you stand two pieces with a seam in the middle? It would make handling so much easier, and I think it would eliminate the possibility of cracking in the middle. You'd still have to beef up the table stringers to hold the weight.

Flo Mangan

hace 3 mesesBry11 - great advise. As an option to soap stone, check out Virginia Mist honed granite. Looks like soap stone but easier to live with. Still need to do what bry911 said. ^^^

jennifernelson24

Autor originalhace 3 meses@L.D. Johnson…thanks for the insight. I actually think I’d be responsible since I’m sourcing the parts myself. This is why I’m so nervous and posting here…lol. The woodworker thinks it will hold the stone and the fabricator does as well; but I get nervous about things like the bolts coming loose from the weight and making the table unstable….or the wood contracting from the weight and cracking etc.

Good point about the castors. If I don’t use wheels though…how would anyone ever move the table? I don’t anticipate it being moved often, but what if we moved or I sell it, or what about when I want to change out the rug underneath at some point…can a few grown men lift and move a table that’s 500+ lbs?bry911

hace 3 mesesÚltima modificación: hace 3 mesesThere are two separate issues here.

(1.) Is the table strong enough to support the weight?

Stone is not really heavy, it is just dense. 3 cm soapstone weighs about 24lbs per square foot… that is not really heavy. The cast iron plate in a grand piano can weigh 500 lbs.

I don’t know the actual diameter of the legs, but I would guess that the average is better than 3” and any areas with a diameter smaller than 3” are actually pretty short (that matters). So I would estimate the weight bearing capacity of at least 4,000 lbs. It is not going to struggle to support the top.

(2.) Is it stiff enough to keep the stone from cracking?

I disagree with your woodworker and fabricator, because I think it will fail.

I put it in the deflection calculator using 68” wide, 3/4” thick, and 3.5” tall for the apron boards with a 300 lb load (half the load plus 50 lbs for people leaning on it). I am getting .26” of deflection.

If your fabricator is willing to guarantee that then he is braver than I am.

ETA: Your woodworker should be able to add steel supports to the table. This is not new territory for most woodworkers. I have to add steel supports to tables, counters, and desks all the time.jennifernelson24

Autor originalhace 3 meses@bry911

I passed your info onto the woodworker. He says:I dont know about the deflection calculator. However, he needs to put in his calculator that the apron will be 1.75” not 3/4”. Does the deflection calculator factor in density and hardness of the wood species used?

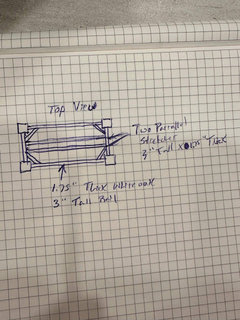

Also is the calculator factoring in four perpendicular supports running long ways?He also gave me this rough sketch. (We are planning on white oak; which is a harder wood)

If you see any issues; let me know.

FYI..he said they have done bases for marble and granite tops before, but never soapstone (which is heavier). If I use granite; it will be about 275 lbs, vs the almost 500 lbs soapstone would be. If the granite seems safer w these plans; I suppose I could consider it, but it seems that you didn’t think the granite would make a difference; plus my heart is w the soapstone.

elcieg

hace 3 mesesMy table is concrete and it took 4 men to get it into the house. I can not move it even an inch.

The base is a 16 Gauge Steel Frame, and then the concrete was applied all around it. I'm going to say your wood frame will not hold the 500 lb top, not for the long run.

bry911

hace 3 meses@jennifernelson24 - You have asked this question on at least two different forums now and have gotten two different sets of math that make it questionable.

Here is the bottom line, if the furnituremaker puts in writing that it will support soapstone, then he is liable when it cracks.

However, he needs to put in his calculator that the apron will be 1.75” not 3/4”.

I did not use 1.75" thick material as that would be pretty atypical. It doesn't actually look like 8/4 stock in your picture. If it is 1.75" thick after dimensioning then it might be fine. Again, since your furniture maker is going to be rebuying it if it breaks and he is comfortable with that, then great... Have at it.

Does the deflection calculator factor in density and hardness of the wood species used?

Yes, I used white oak in the calculator.

Also is the calculator factoring in four perpendicular supports running long ways?The perpendicular stretchers are going to carry the weight to the longer boards, they are not added into the calculator, if they were, their weight would be added to the soapstone but I figure they are minimal and not worth adding into the calculation.

Using the new information (1.75" thick, 3" tall) I am getting sag of .18" at 68". Please understand that I don't actually know the length of the apron boards. I am just using 68" because that is the only number I have. At 60" length that goes down to .12" of sag.----

I don't know if that is good enough. Of course, we know that the flexural strength of soapstone is between 10 and 17 MPa, but there is a problem using that type of data to calculate the flexural failure point of a natural stone. We don't really know about internal weaknesses in the stone. There is a similar problem calculating sag as it assumes that wood is clear and free from knots and other structural defects, which are typically easier to detect in wood than in stone.

As for your sketch... it is better, I would add one or two perpendicular stretchers just to keep the wood from flexing, but that might be overkill. Using four boards that are all 1.75" thick we can probably get closer to .006" of sag. However, that is more expensive than just adding steel and whether that is stiff enough is something I don't know.jennifernelson24

Autor originalhace 3 mesesBry911…I do appreciate your feedback and help. I did post this on another board I was directed to…and honestly don’t understand the answer, and neither did my woodworker. I guess I understand generally that the math is questionable, but don’t really understand the specifics. I have shown him all these responses though and between the both of us, we are trying to figure out what would work…with neither of us being civil engineers or having that type of experience.

He has told me they have done granite tops that were fine, but soapstone is not something he’s worked with before. He is out of state, and is trying to work with me, but he isn’t going to guarantee it and pay for it if it fails..nor would I expect him to, as he is only doing what I’m telling him to from information I’m only half understanding off of the internet. I have asked a few different fabricators and table makers and they all seem to say it will work, but it’s me who is not confident.

He also said we could use 3.5” skirt/rails. And the 1.75” white oak frame is thicker than their standard 1.25”. The pic attached is not my table, but an example pic he sent me.

I am still a little unclear as to why a granite that is half the weight would still be an issue. It seems to me (and maybe I’m wrong), that the weight of the stone is what would cause the issues we are discussing.As of now, I am not confident enough to move ahead with my plans though! I didn’t realize when I started this project that it would become so confusing.

bry911

hace 3 mesesÚltima modificación: hace 3 meses“He is out of state, and is trying to work with me, but he isn’t going to guarantee it and pay for it if it fails..nor would I expect him to”

He doesn’t really have a choice. He is selling a physical good and therefore is governed by the Uniform Commercial Code. There are three implied warranties in the UCC, one of which is the implied warranty of fitness for a particular purpose… it basically says that if the furnituremaker knows what you intend to do with the table it must perform that use acceptably. Normally, there are specific instructions to notoriously disclaim the implied warranties but that would be really difficult in this case as he can’t say it will be fine only to then disclaim that.

I am struggling with the hesitation from your woodworker. If your table isn’t actually built it is exceedingly cheap and easy to add steel supports.

Two 60” long 1/8” thick, 2.5” tall cold rolled steel bars are $66.72 plus tax at Metal Supermarkets.

(1) Drill holes in the steel every 6” or so. (2) Make your apron boards like normal. (3) Raise your table saw blade just over 2.5” and set your fence about 3/4” from the face (assuming 1.75” apron boards), run the boards through to carve out a groove, move the fence over and repeat until your groove is at least 5/32” wide. (4) Tape the ends and fill the groove with liquid epoxy (West or Total Boat are both great). (5) Drop the steel into the groove, the liquid epoxy will soak into the wood and harden through the drilled holes forever locking the steel and wood together. (6) Complete the table like normal (the boards can still be planed and sanded on three sides, just remember there is metal in the middle so choose fasteners accordingly).

Sleep like a baby…

jennifernelson24

Autor originalhace 3 mesesBry911 Regarding the hesitation of the woodworker…he said he doesn’t think the top is heavy enough to require using steel and that white oak is a strong enough wood species to hold the top. This is what he said originally, I haven’t showed him your most recent responses yet..so maybe with more info he will say differently.

Can you clarify for me…if I do switch to the granite, which is 2cm and half the weight, would you still recommend the steel?bry911

hace 3 mesesIt is a table and not a piece of artwork. Is someone going to lean on it, sit on it, drop a heavy box on it, etc?

Suppose someone hops up on the middle of that table, that dynamic load may be several hundred pounds for a moment. That may never happen, you may never have a significant load in a bad place, so it may never be a problem.

As for granite… I really don’t know. In general, thinner material is not as strong as thicker material but it is lighter. So changing from 2cm to 3cm of the same material will reduce the likelihood of the wood sagging from fatigue but increase the likelihood of a break from a dynamic load. As for switching materials I really just don’t know.

Volver a cargar la página para no volver a ver este anuncio en concreto

M Miller