How to deal with Landscaper who didn't deliver...

Hi everyone, wanted to see what you all think about this situation and any suggestions or comments are appreciated.

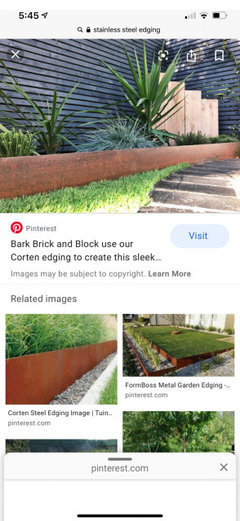

I am redoing the front yard and putting in some custom height 10" weathering steel edging. There is a slope to my yard and I had wanted to make sure to have very clean modern lines and that the top of the edging is leveled. I communicated these expectations to the landscaper, who I worked with 2 times previously with no problems.

Fast forward two weeks later, the project started, and the steel planters were fabricated, and we ran into problems...first, the steel edges are not straight, so he suggested we go to a thicker gauge and he says this will allow straight rigid lines. I then agreed to pay this additional cost. And then after that part is redone, I was informed that my slope is a lot more steep than what he expected, and that he is unable to level. And the thicker material is still warped. His solution for the warping is to have unsightly stakes on the outside to keep them in place, which defeats the purpose of the custom edging that's supposed to give a clean and straight planters look.

So now I am stuck with the steel edging that's not leveled nor straight. Now he's wanting more money to fabricate taller edging to address the level issue, and want to regrade my yard to hide the stakes on the outside to conceal it, and I have to bear the additional cost once again.

What would you do here? I want to be reasonable, but this is not what I had asked for, and I feel like this is their first project with steel edging hence the inexperience in installation/execution.

Comentarios (11)

Revolutionary Gardens

hace 4 añosI'd also be curious to see your inspiration pics, if there's a look you were trying to emulate.

Yardvaark

hace 4 añosI've never installed this material so don't know how it is done. Apparently the contractor is learning how to install on the job and now you're both regretting it. Longitudinally, it looks fairly straight but the stakes are atrocious. Hard to make a judgement of the photo showing out of level because it is a bad photo and shows no surroundings. Need full size photos taken from outside, same view. Maybe a series of overlapping shots while standing at one spot. (I'm not saying that it might be level, I'm asking about the importance of it, and I mean the landscape importance, not its importance to you personally.)

I'm looking for a way out -- a save -- not advising as to what you are legally or rightfully entitled to. (I'll leave that up to the more technically astute hardscape experts.) So I'm kind of looking at this like, 'what if this was mine and I had done this to myself?' Rather than regrade to hide the horrible looking stakes, Since it's not going to work without stakes unless it is rebuilt (which I wouldn't do after all the bother I've already put into it) I'd be inclined to change the concept to include nice looking, beefy, custom stakes spaced at uniform intervals that are a featured part of the work. (I know this is against your original concept, but it's where I'd go.)

If the surroundings warrant it being perfectly level, I would change it to be so. But not all surroundings warrant that. Would like to see what they are here.

BTW, it doesn't sound like this work is coming about from a drawn plan and written notes/specs so much as it is from a verbal discussion. If so, that would be the first problem that doesn't work in your favor.

danielj_2009

hace 4 añosI'd say that looks like a very long run and I'd think it very difficult not to have some amount of warping. I'd bet there is some warping in your inspiration photos. Does the soil in the planter fill up to the top edge of the steel edging? I'd expect some warping over time just from that. Freeze/thaw if in a cold climate, etc.

I think you might be able to lessen the warping by putting a length of angle iron on the inside of the edging maybe a couple of inches down from the top edge, below soil grade. Only problem is you'd have to weld them in unless you want bolts showing through.

I agree with Yarvaark. Seems like this is being done on the fly by someone who doesn't really know what to do. Is it possible to contact the people where you found the inspiration photos and contact whoever did that work for advice? I would consider holding off on any further work until you get advice from an expert in this area, if there is such a thing.Revolutionary Gardens

hace 4 añosEven if you beef up the steel thickness to where your garden gnomes can take cover from a delinquent with a .30-06, you may likely still get deflection and wiggles. Like danielj said, you need reinforcement on the back. Personally I'd weld two pieces of angle iron or two pieces of 1" square stock top and bottom, then drill holes at intervals to secure them with rebar pounded into the ground. As far as your grade issue goes, the only way to properly address this is to run a string line at the desired height to either a) see how tall the edging is at the end or b) figure out where/how to step it down to follow the grade but keep the tops level.

I think your ideal compromise solution is to have your landscape guy install whatever is designed by a metalworker and/or a landscape designer. If you go looking for a landscape designer, just be aware that most of them don't have any more experience with metalworking than your installer so ask lots of questions and ask to see examples of prior work.Yardvaark

hace 4 añosÚltima modificación: hace 4 añosOne of the things I don't like about the look of this material in the typical installation is that it looks weak. If indoors it would seem thick, but In the landscape it looks like a thin piece of metal sheeting that is supposed to act like a retaining wall. We all know these walls hold incredible forces so generally must be very beefy in order to handle them without failing. It would look more like it could handle the forces if it looked several inches thick. I have another idea that would solve the visible stake problem while simultaneously make the steel look more substantial. (This is completely independent of the leveling issue, for which we're waiting on more information.)

From the front side, no stakes would show. They'd be at the back side, their tops hidden by the continuous cap. Stakes would be spaced at intervals as required to hold the "wall" steady. One could see a sample of the finished look simply by temporarily setting a section of cap in place. Since the stakes would be welded to the the cap, holding it in place, the cap would hold the Corten steel "wall" by overlapping it, without welding.While it is not the same as the original concept, IMO, it is an improvement in it .... making the wall look much more substantial, while still keeping clean lines (no visible stakes and no regrading outside of what should otherwise be done.

Derviss Design

hace 4 añosÚltima modificación: hace 4 añosThere are a couple of solutions : evenly space the tack welded posts to even out and stiffen up the undulation.

The posts and welds should be on the inside of the planter for a nice clean exposed face.

If the material is just too thin then purchase a thicker "L" ( 2" x 2") shaped cap and tap weld it to the top .

Attached is an example of a metal wall with a cap ( much larger than what you require )

The added benefit of a top cap is the ability to add strip lighting under the lip.

krnuttle

hace 4 añosThere is one basic physical principal that is being over looked, that of thermal expansion. It looks like you have 20 to 30 feet of a continuous strip of metal with no expansion joints. The metal will expand and contract as the temperature changes. This expansion effect is further emphasized as the top part of the strip will be in the environment and the bottom is in concrete. This will cause a temperature difference between the constant temperature cause by the buried contact, and the top which will be exposed to the sun.

Bottom line the design may make your desired results nearly impossible to obtain.

Volver a cargar la página para no volver a ver este anuncio en concreto

Yardvaark