Ipe horizontal privacy fence advise

I'm planning on building an 8' tall x 12' long horizontal Ipe or Cumaru privacy fence. It's going to be divided into 5 approximately 36" wide panels of either 5/4x4 or 1x4 Ipe boards held up by 5 4x4 posts. It will be on top of the edge of a semi-circle concrete patio. The posts will have vertical channels attached on the sides into which the wood slates can be inserted and then screwed to. The posts will probably be aluminum.

The 36" wide horizontal boards are going to be T&G so that there will be no visible gap (maximum privacy) regardless of the time of year. I live in Georgia so there is a lot of wood expansion during the summer. The plan is, to place the tongue and groove tongue side up, the boards are to be placed at a slight horizontal pitch (for moisture runoff), with the tongue and groove engaged appropriately for the season at the time of construction - shallow in the winter, deeper in the summer, allowing for future contraction or expansion........Wanted to get some feedback/advise, on whether this plan is likely to work, potential issues etc....There is a lot of info online regarding decks using the Brazilian hardwoods, but I haven't found any on privacy fences where no gaps between slates is the goal. Also, am seeking any advise regarding how far for the edges (both from the ends and from the sides) of the wood slates is optimal for drilling pilot holes .....from what I've read, if the holes are too close to the edge, this can lead to the wood splitting, either immediately, or down the road.....trying to determine how deep to make the channels......

Comentarios (10)

AdvantageLumber.com

hace 4 añosI would hesitate to recommend this plan. It sounds like you've thought it through and are taking steps to minimize any potential issues, but T&G was just not meant for this type of application.

Instead, I would recommend an actual siding profile. The best one that addresses your concerns would be a rainscreen profile: https://www.advantagelumber.com/rainscreensiding/ It's a modified pregrooved shiplap profile that allows for a hidden fastener system (good for expansion/contraction) while also blocking any see-through gaps.Tone Sg agradeció a AdvantageLumber.comMark Eric Benner - Architects, Ltd.

hace 4 añosI understand the intent behind the T&G, to maintain alignment and maintain privacy. The challenge is not only expansion and contraction, but warping. You are wise to reduce the span of the planks as this will help. An improved detail would be to mount the ipe onto a frame., similar to that suggested by @AdvantageLumber.com.

As for the end splitting concerns, there is a lot of guidance from the suppliers on how to address this. Simply cutting the board exposes the risk of splitting. An end cut treatment, a wax-like paint is typically prescribed for all cuts.

Tone Sg agradeció a Mark Eric Benner - Architects, Ltd.Tone Sg

Autor originalhace 4 añosThanks everybody for the detailed, helpful responses. It does look like using siding (rainscreensiding) and framing would be the better, less problematic option.

ElementLumber.com

hace 4 añosProbably a little late to respond, but here’s our two cents.

Rainscreen Siding is exactly that. Siding. Not a fencing profile. Utilizing a stainless steel Rainscreen Clip system with aluminum channels or posts will create a galvanic reaction between the steel and the aluminum causing corrosion and ultimately the failure of the system. Even if using wooden posts and rainscreen clips at the end of the three foot span... why employ an expensive clip system when you could accomplish the same effect using a shiplap profile and screws. Don’t get me wrong, love Rainscreen and sell a lot of it...., but just not for this application.

Wood stability primarily comes from the ratio of thickness to width. The thicker and narrower the more stable it will be. Factor into the ratio the length of the board and the frequency of fastening and that will ultimately determine how resistant to cupping and bending the material will be. In this instance, 5/4x4x3’ should be perfectly adequate to accomplish what you’re trying to do. You have at least three good options. Later this week I’ll post some pictures of a 2x4 vertical fencing project we’re just finishing up that will give you an idea of just how stable this material can be.

Option1: If still using the aluminum posts slide the boards into the channel and screw through the channel into the wood (add some silicone around the screw head to create barrier between the steel and aluminum to cut down on the galvanic reaction. For added security you could essentially add a furring strip on the back side of the fence at the halfway point in between vertical posts and secure it to each board to help keep the boards aligned.

Option 2: Use 4x4 Cumaru wood posts and cut a dado out on either side of the 4x4 to slide the horizontal 5/4x4x3’s down into. Screw on a 45 through the board into the posts. For added security you could essentially add a furring strip on the back side of the fence at the halfway point in between vertical posts and secure it to each board to help keep the boards aligned.

Option 3: Use 4x4 Cumaru wood posts and simply face screw the boards to the face of the post. For added security you could essentially add a furring strip on the back side of the fence at the halfway point in between vertical posts and secure it to each board to help keep the boards aligned.

End checking. If purchasing from a reputable supplier, every board will come with Anchor Seal applied to the ends. As Mark suggests, if you cut a board you will need to reapply the anchor seal to cut down on end checking. It’s very inexpensive and easy to apply.

End splitting caused by screws. Always always always predrill every screw hole whether in the middle of the board or near the ends. The hardness of the wood will cause splits to open if not predrilled. Try and set your holes at the ends at least a half inch back from the edge.

Would love to see some pictures of what you ended up doing!

Tone Sg agradeció a ElementLumber.comTone Sg

Autor originalhace 4 añosElement lumber,

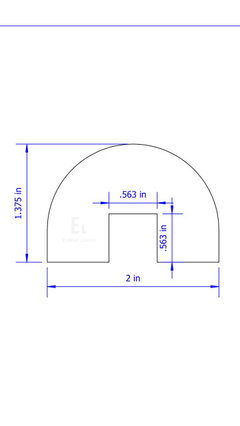

Thanks for the detailed info. regarding the fence. For a variety of reasons, i've gone in a different direction, and am now considering a portable privacy screen made of panels connected by piano hinges, in IPE frames......either pvc board or fiberglass sheets will be used as the filler. There will be six panels roughly 30" wide each, and again, about 8' tall. The IPE frame will have 2"x2" (actual 1.5x1.5") posts and horizontal beams....We plan on routing a 1/2" channel the length of the posts, about 1/2" deep, for the pvc to slide into, which may then be attached by ss screws through the posts into the PVC in the channels. The PVC is exactly 1/2" thick. The fiberglass is 1/8" thick, which would allow a narrower channel, but it's more expensive, has to ship (is oversized), and isn't readily available...may not be able to get more if we need more down the line....... hence am leaning towards the PVC, which is readily available from HD. I am concerned about the effect of the 1/2" channel on the 8' IPE post's stability..splitting..warping......etc......would welcome any opinion regarding that.....4"x4" posts would be too heavy for this application.......would really like to get away with the 2x2 posts, due to the weight - also, everything will look more integrated/balanced with the thinner posts.ElementLumber.com

hace 4 añosHi Tone, a lot of variables and no clear cut answers..... might you be fine with 2x2x8 square with 1/2” dado using pvc or fiberglass? Yes, but our intuition says the wood may move on you. Monday will share some pics of a 2x half round we did with a dado for a NYC roofdeck and another in Miami which is basically unsupported vertical 2x4’s, but it’s secured at fairly regular intervals. If you’re going to stick with the 2x2 splurge on the fiberglass. I’d consider a bracing piece on the outside of the fence at the mid point. Unfortunately, we won’t get a definitive answer until after you’ve purchased and installed.... As an alternative, how about a 3x3? We should still have some in inventory and can check when we reopen Monday morning. We can put the dado in for you, but not sure how you’re finishing off the corners where the vertical and horizontal meet. If we’re just running the dado the length of the board then that shouldn’t be problem. Give us a shout or message us and we can chat about it.

Tone Sg agradeció a ElementLumber.comElementLumber.com

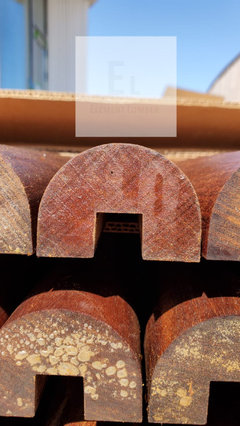

hace 4 añosHi Tone, We have some 2x3 in stock that would probably be your best bet in terms of pricing and fit the bill unless you want square (also have 3x4 available), but then for this project where we milled 698 pcs of 12' half rounds we took it out of our 3x8 and yielded 3 pcs from each piece of 3x8. We also prefinished it with Penofin because the customer insisted, but generally we do not recommend pre-finishing and encourage finishing on site after install.

ElementLumber.com

hace 4 añosShould've added to the half round above... that was for a NYC penthouse roof deck wall in Hudson Yards. Roughly 1500 sq/ft. Customer custom manufactured a stainless steel cladding system with vertical "channels" that the dado slipped onto and then was secured from behind with ss screws that passed through the channel and into the ipe so that no screws were visible from the outside. Been installed for several months with no problems reported

Here are pictures of the 2x4 Ipe fence (+4x4 and pregrooved ipe decking utilizing the EbTy Precision Clip for Ipe) we recently supplied in Miami that is a testament to Ipe's stability. Hasn't been oiled yet as the customer is contemplating letting it weather grey. Regardless, super cool fence that has been installed for several months with no issues reported. Actually sending them some more 2x4 to build an extension they hadn't anticipated doing originally.

A.W Carter

hace 4 añosHere is a product we and have great success. The shelf life is amazing!

It is a very simple method and can be applied by yourself, having several options. Contact us if you have any questions at all. Happy Holiday.

Derrick KeiselA.W. Carter

Volver a cargar la página para no volver a ver este anuncio en concreto

Patricia Colwell Consulting